LOEW Präzisionsteile GmbH: From paper to digital production

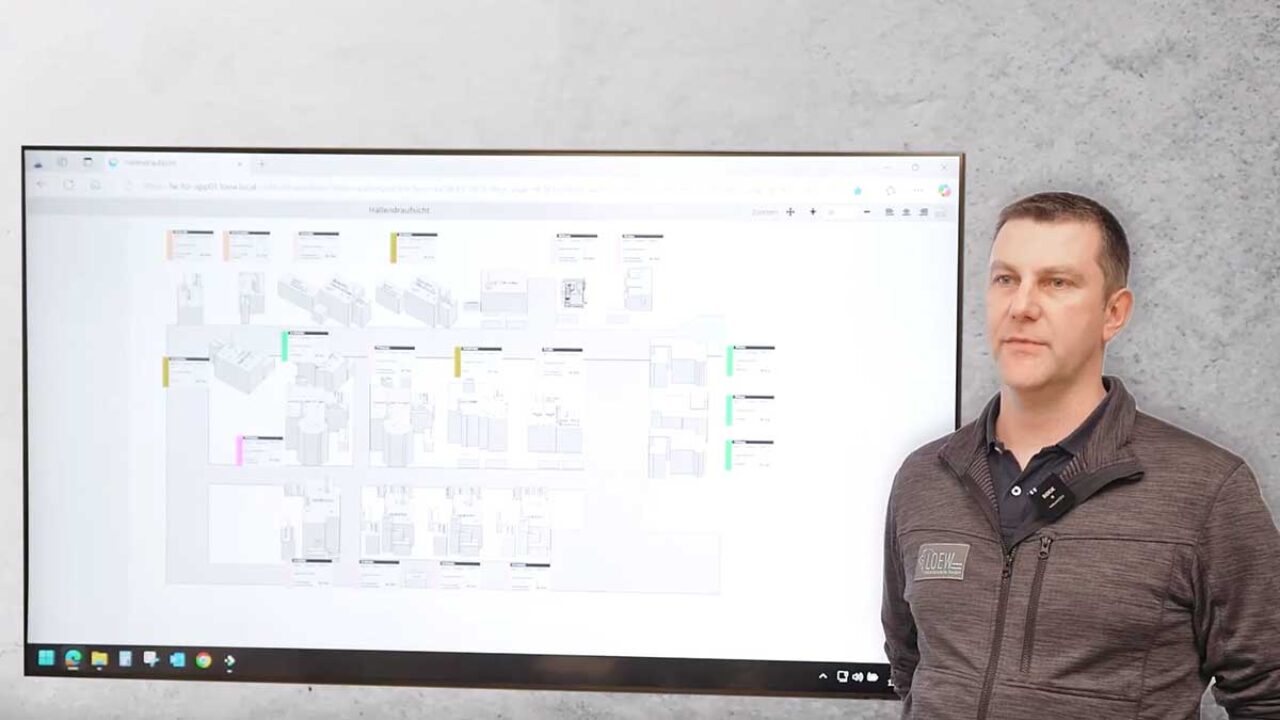

Successful digital transformation in medium-sized companies: Find out how LOEW Präzisionsteile GmbH in Nuremberg produces more efficiently with digital production and the MES FLEX solution from FORCAM ENISCO.

Harald Hufnagel Managing Director LOEW Präzisionsteile GmbH: “Digitalization is very important to us. We always have an overview of the order status and the cost structure, while at the same time providing standard-compliant documentation”.

In the Success Story you will learn how LOEW is an example for successful digital transformation in medium-sized companies – through digital manufacturing and the solution MES FLEX, the powerful Manufacturing Execution System from FORCAM ENISCO.

The added value for LOEW – all order data at a glance:

- Operators have all order data at a glance with one click

- More clarity about the workload per shift

- Improved adherence to delivery dates

- Valid data for ISO documentation

- Optimized order calculation through precise shop floor data

You would like to learn more about digital manufacturing at LOEW?

Fill out the contact form and you will receive the complete document immediately by e-mail.

About the company LOEW

LOEW Präzisionsteile GmbH from Nuremberg is a certified, reliable and competent partner for precision parts and machining. The company has been manufacturing the most demanding high-tech components for 30 years.

With 50 highly qualified employees, LOEW has specialized in the manufacture of complex components from various materials as well as their finishing. Its customers come from a wide range of industries, especially medical technology, aerospace, defense and optics.