The Right Solution for Every Situation – FORCAM-ENISCO’s MES Product Portfolio

Our Positioning

FORCAM and ENISCO are pioneers of Industry 4.0:

As a group of companies under the umbrella of FORCAM ENISCO GmbH, we support companies with discrete manufacturing to sustainably secure their competitiveness. Our modular MES solution world for data-driven manufacturing covers every stage of a digital transformation.

Our MES Portfolio

With over 20 years of experience, we offer you a modular MES solution world for data-driven manufacturing and accompany you step by step on the digital transformation of your production.

From connectivity of heterogeneous machine parks to machine data acquisition (MDA), production data acquisition (PDA), performance analysis (OEE), detailed planning, traceability and document management, we offer you the shortest path to the smart factory. In addition to the ability to map, monitor and control complex manufacturing processes, we ensure effective manufacturing operations and increase your productivity by collecting and processing real-time data throughout the entire production lifecycle.

From production to planning: the IT levels in manufacturing companies – FORCAM-ENISCO’s MES solutions form central data hubs for all systems and network production both horizontally and vertically

In detail, we support you in the following application scenarios, among others:

- Reduction of the scrap rate

- Increase of the machine availability

- early detection of process deviations

- Traceability of production units

(track and trace) - real-time visualization (reporting)

- Identification of equipment with

deviating energy consumption (energy monitoring) - reduction of planning effort (detailed planning)

We support our customers from the automotive, medical technology, aerospace, manufacturing, mechanical and plant engineering, precision mechanics / optics or metal industry sectors in joint innovation projects to increase productivity on the shop floor by up to 20 percent.

We at FORCAM-ENISCO also want to support you in organizing your production even more efficiently. We look forward to exchanging ideas with you about which solution is best for your plans!

FORCE MES LITE – Start Smart Manufacturing Easily and Quickly

Record machine setup times, analyze unwanted downtimes, control performance and quality in real time – With the MES LITE solution, you can produce more efficiently and significantly increase your factory capacity in just a few days.

Added Value

- Machine status & availabilities (MDA)

- Order status for the top floor (ERP)

- Real-time exchange between shop and top floor

- Downtime reasons, quantities, quality (OEE)

- Minimum >10% higher capacity

- Modular expandable solution

With FORCE MES LITE, Monitor Production Virtually and Optimize it in Reality

Machine and order data at a glance at all times: The MES LITE solution ensures transparency and efficiency in production. The modular solution is easy to install: After just a few days, companies can start digital production and empower their employees to use raw materials and energy even more efficiently.

The first step towards transparency in production is machine and production data acquisition (MDA/PDA). Particularly helpful: If factory teams know the reasons for unwanted machine downtimes, they can actively contribute to increasing resource efficiency and reducing costs

Example NMH GmbH:

Smart Factory in Record Time

With the right technology, a smart factory can be up and running in just a few days. Example NMH GmbH from Baden-Württemberg: The “hidden champion” for complex measuring, testing and assembly systems connected pilot machines with FORCAM solutions in record time and integrated them into the existing IT architecture – including ERP networking. After just one week, NMH workers were working with real-time analyses on…

- Utilization of the machines

- Downtimes

- Reasons for errors

NMH Managing Director Christian Bulander:

„For our mission of paperless manufacturing, we can ideally complement our own COCO manufacturing software with FORCAM solutions and thus obtain an end-to-end digital solution on a wide variety of machines.“

FORCE MES FLEX – Make Your Manufacturing Flexible and Sustainable

FORCE MES FLEX serves as a flexible data hub in the factory: you orchestrate tasks and processes according to your individual needs. All important MES apps are integrated: Performance analysis (OEE), energy monitoring, detailed planning, traceability, document management. The solution is particularly suitable for manufacturing with high product variants (order and small lot production).

Added value

- Modular solution especially for job order and small lot production

- Uniform data model

- ERP integration – own SAP adapter

- Digital image of the production

- Real-time analytics through integrated MES applications

- Open interfaces for third-party apps (workflows, AI, etc.)

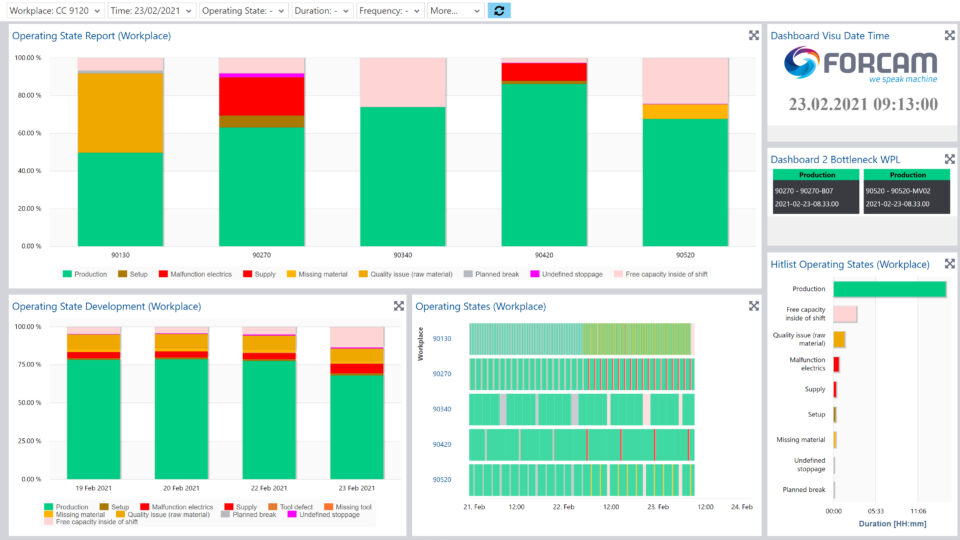

Control Production With Configurable Dashboards

With MES FLEX, you analyze and optimize your manufacturing processes and produce more efficiently, sustainably and resiliently.

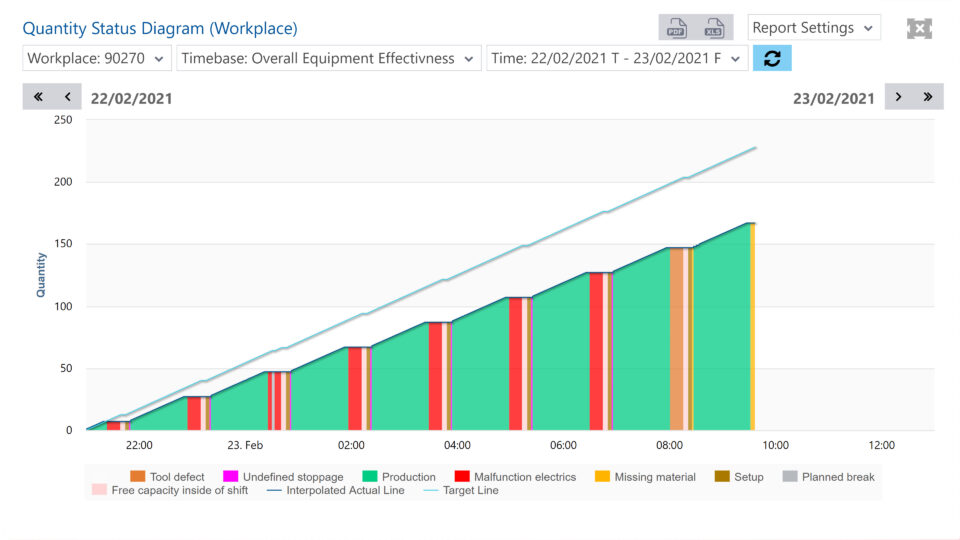

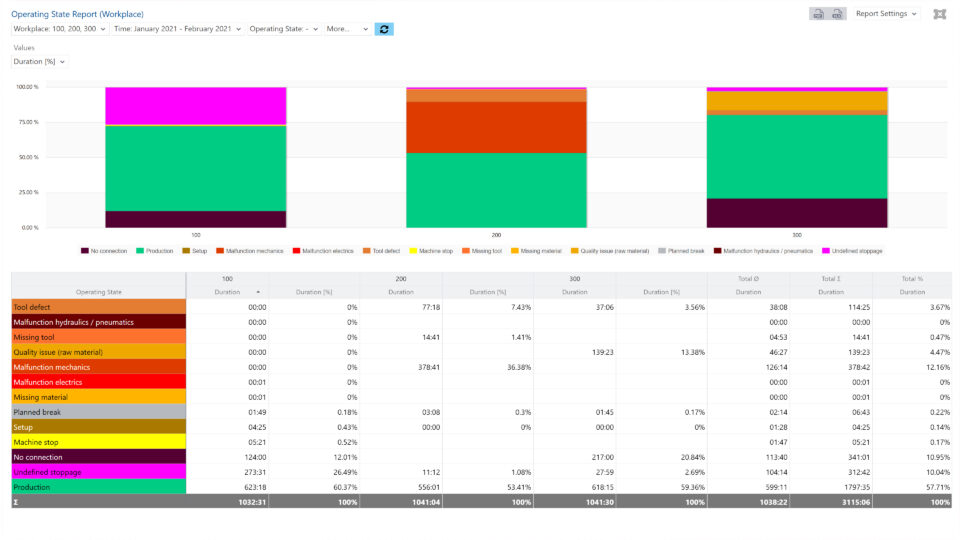

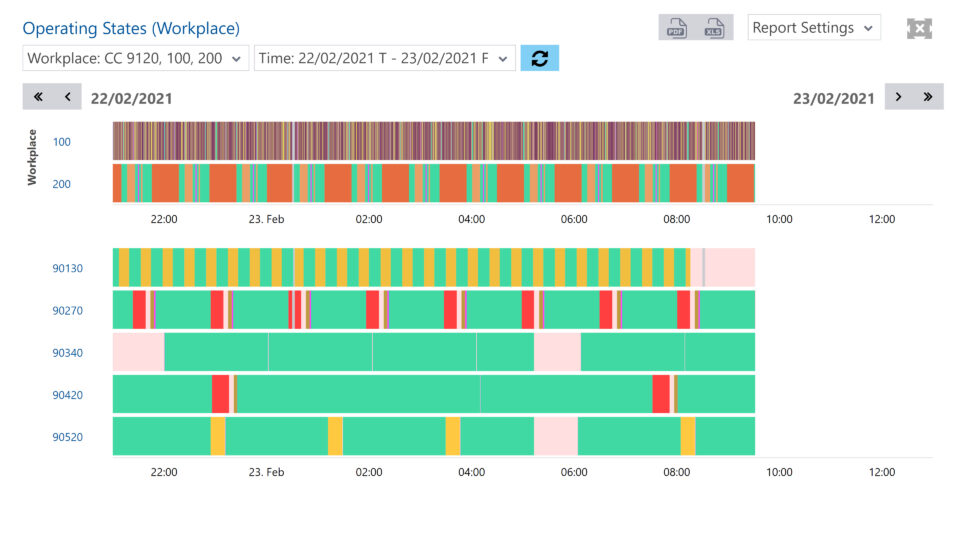

Availability, performance, quality, quantities, scrap: Everything in view on a central user interface (dashboard). An important indicator for factory teams is the Overall Equiment Effectiveness (OEE), displayed in real time as well as in historical analysis.

Example SWAROVSKI OPTIK:

Mission Digital Twin

SWAROVSKI OPTIK from Austria manufactures high-precision long-range optical devices. The demands on development and production are correspondingly high. In order to reconcile sustainability and economic efficiency, all business processes are being digitized: Customer approach, products, manufacturing, service. Digital twin mission: In manufacturing, the mission is called “digital twin”: The goal is to fully simulate all production and logistics processes of the international manufacturing network using a digital image. To create a uniform production network, SWAROVSKI OPTIK relies on MES FLEX.

Dr. Gerd Schreiter, Chief Technology Officer at SWAROVSKI OPTIK until the end of 2021:

„We can reduce production costs because the machines have high availability and we have to buy in fewer resources.“

Control Semi- and Fully Automated

Processes Highly efficiently

E-MES is a leading solution for controlling semi- and fully-automated lines – from paint shops to high-bay warehouses. You benefit from consistently transparent production and logistics processes. The solution networks the factory both horizontally across the manufacturing process and vertically across all process levels.

Added value

- Event-based control of highly automated production plants

- Horizontal & vertical networking of all manufacturing processes

- Integrated modules for data acquisition, analysis, visualization (2D/3D)

- Real-time transparency with monitoring apps & manual intervention options

- Reduced lead times through automated allocation of critical resources

- Configurable material flow through the plant

With E-MES, You Benefit From Comprehensive Production Control

The E-MES solution is platform-independent. All the necessary tools for data collection and analysis are included. Your teams configure the flow of materials through the plant with one click of a mouse and automatically control production based on product requirements and machine potential.

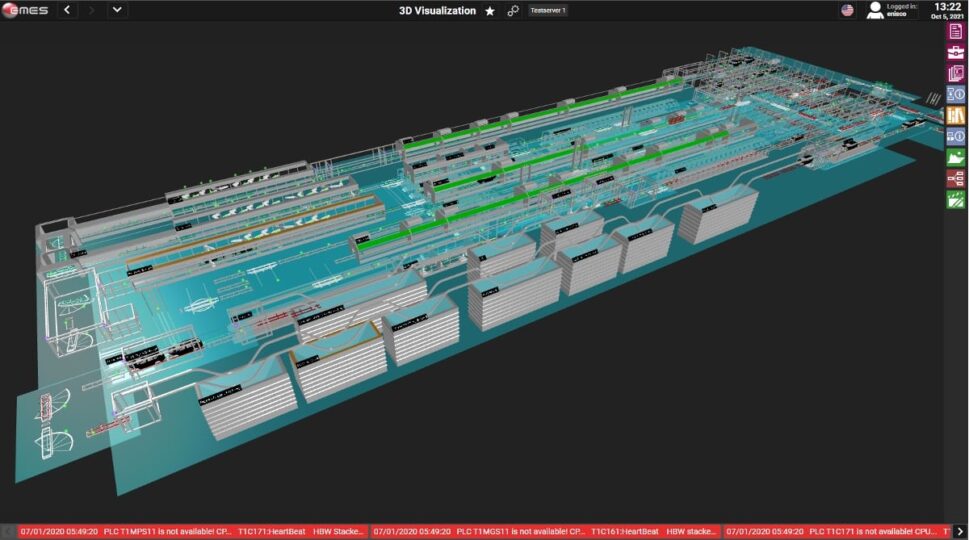

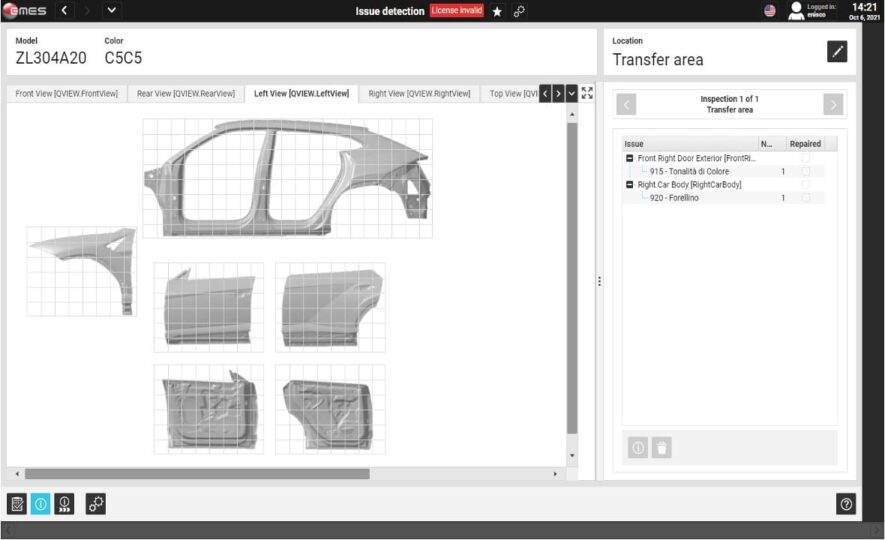

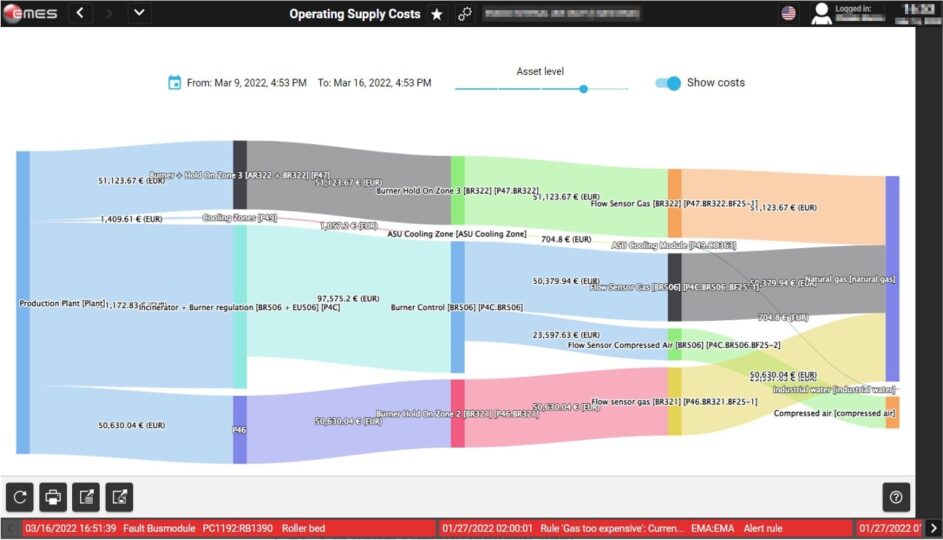

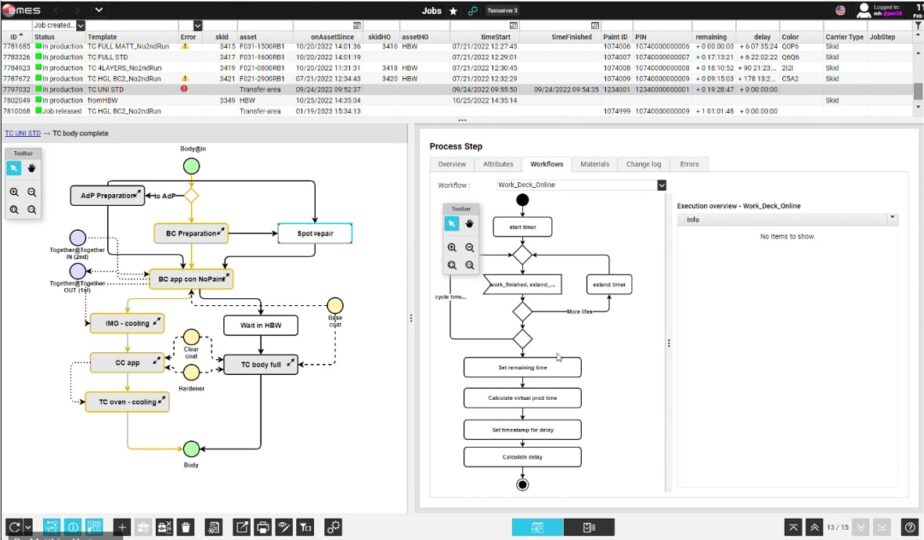

Examples of user interfaces for the E-MES solution: ENISCO’s MES enables smart production – the right information at the right time in the right place for every process step, whether in 2D or in 3D.