New Manufacturing Experience: How companies are empowering their factory teams to master digital transformation easily and quickly

For the first time, companies can empower their factory teams to work more efficiently and autonomously with market-renowned apps – through a bridge to the Microsoft Power Automate app universe.

We use smartphones and apps to shop, get help, chat, post, or stream globally in real-time. Digitalization is making our everyday lives much more convenient.

Digitalization is also advancing rapidly in the manufacturing industry. The goal of “Industry 4.0” and “Industrial Internet of Things” (IIoT) is to increase efficiency in companies and thus secure competitiveness, locations, and jobs.

McKinsey estimates the value creation potential for manufacturers and suppliers through Industry 4.0 at 3.7 trillion US dollars in 2025. The analysts see three fundamental principles in the study on the manufacturing sector “Industry 4.0 – Capturing value at scale in discrete manufacturing”:

- put people at the center

- focus on value creation

- Establish a new integrated infrastructure

Focusing on people and value creation, the intelligent factory is also changing the way work is done in factories: Workers control machines digitally via tablet and smartphone, factory teams analyze the results of their shift with digitally created charts, factory managers monitor the status of production orders in real-time at digital control stations.

Organizing Factory Work 4.0 more efficiently and with more significant value creation with the new connector

Now Factory Work 4.0 is even more accessible and more value-adding. Because what has been missing until now is the possibility of using all those apps in manufacturing that we all know from our office and private everyday life.

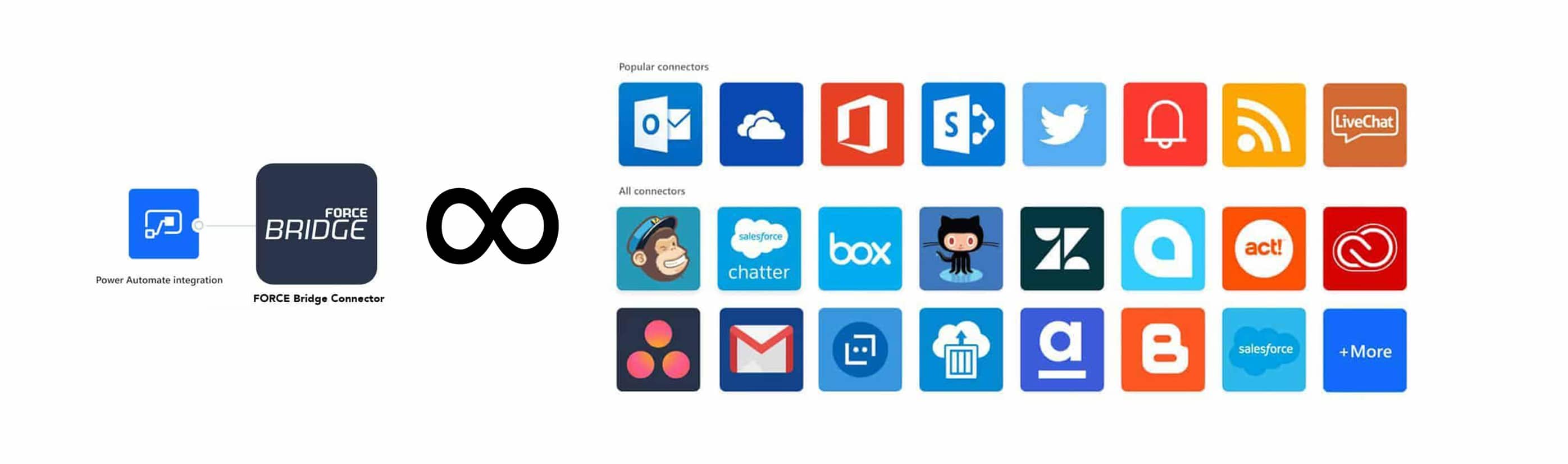

A new tool is now building such a bridge between apps we know from everyday life and factory work: The FORCAM connector “Bridge API,” which is freshly certified and integrated into the app universe of Microsoft Power Automate. With the FORCAM connector, factory teams can, for the first time, tap into the Microsoft ecosystem of more than 400 market-renowned apps – including Excel, Facebook, Outlook, Skype, Trello, and many more.

Many production processes can be organized with minimal effort, without programming, in a much more time-saving and, therefore, value-adding way. Factory teams can be empowered to act more autonomously. Examples:

- Bottlenecks: A worker suddenly needs new material or tools to complete a production order on time. With a click, the person can invite the responsible logistics team to an immediate meeting, for example, via team message or online ticket (JIRA, Trello, etc.). Valuable time is saved, a standstill is avoided.

- Key performance indicators: Factory teams inform themselves automatically and regularly via email about target and actual, for example, the overall plant effectiveness.

- Process values: Sensors can also trigger workflows via apps, for example, when pressure or heat values are exceeded, or new material is required.

The technological home port of the connector is the turnkey and adaptable IIoT platform solution FORCAM FORCE™. It enables companies to freely and flexibly compose their own IT architecture.

With both together, the new connector Bridge and the integrative IIoT platform solution FORCAM FORCE™, companies have for the first time a concrete vehicle to digitally transform their manufacturing along with the three fundamental principles easily and quickly.

Do you want to know more about this topic or our products?

We will be happy to answer any open questions.