Highly diverse machine facilities connected simply and digitally – Episode 1: Presses

According to a McKinsey study, digital transformation is a major priority for 69% of industrial businesses, with 60% of companies saying they have to replace around 30% of their existing plants. Help is at hand: FORCAM and SAP are working together to enable the highly diverse machinery among existing “brownfield” plants in industrial companies to be connected digitally, and their data ported across to SAP’s “digital supply chain”.

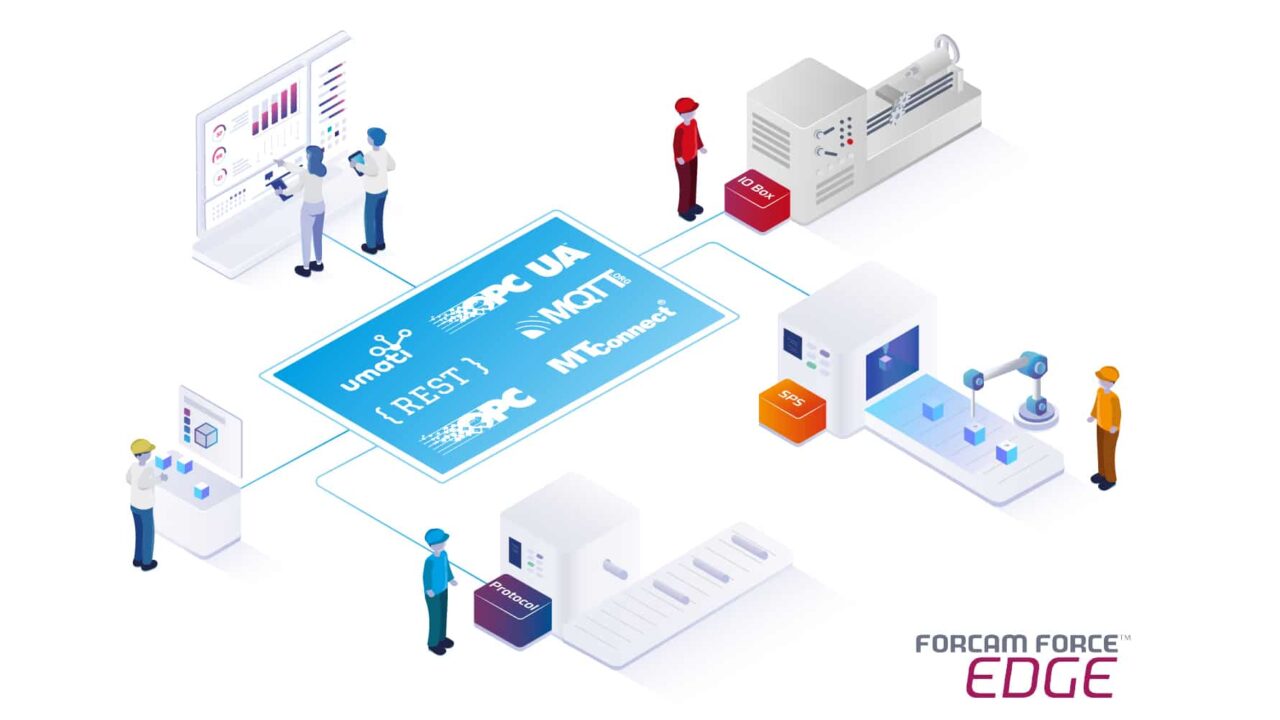

In six articles for common machine types, we outline how companies can use the FORCE EDGE CONNECT connectivity layer to connect all machines – regardless of manufacturer, vintage or control system – and process the data for example in the SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII.

Episode 1: Presses

In factories, pressing machines handle a very wide variety of tasks – primary shaping, forming, joining and dividing – and the various members of the large family of pressing machines are correspondingly diverse. During any digital transformation, however, it is important to take a uniform approach to connecting assets in highly diverse plant inventories – i.e. machines of differing vintages and from differing manufacturers.

In this blog entry, we look at the relationship between machine connectivity and presses. We use the term “presses” generically, covering both

- a simple press running one production order on one material with one operation to operations with several pieces per stroke (one stroke = 1 piece or one stroke = x pieces),

and

- complex presses on which two operations using different materials are undertaken at the same time. Car doors are a good example – in automotive press shops, modern systems complete the left and right-hand vehicle doors at the same time with a single stroke. This example can be applied to all types of presses.

Making the digital connection

The following procedure is recommended for digital connection of presses:

- First, it is important to identify a reference machine (press). This is selected from a group of presses of the same type, the most commonly found group in the plant. This way, the reference machine can subsequently be the one used most often as a copy template.

2. The second step is to connect the machine physically. To do this, the connection type and the necessary plug-ins are selected. The questions to be asked are:

- Is the press essentially capable of being networked? (If not, can it be connected via the FORCAM I/O box?)

- What type of control system is used in the press?

- What are the relevant signals (reading/writing)?

- Is it necessary to send and receive NC programs?

3. The third step looks at the actual production workflow. This means an analysis of how the press is integrated into the production process and how production is organized around the press. This checks, among other things, whether the press is in a

-

- workshop,

- standalone production setup or

- production line

from an organizational point of view. These processes are usually individual to each company and cannot be transferred 1:1 to other sites as a blueprint.

Basic setup architecture

The next step is to map the process requirements onto the FORCAM solution portfolio. This creates a basic setup architecture which is based, say, on the following scenario:

The machine or its controller supplies operating status information via the FORCAM FORCE™ plug-in to the “FORCE EDGE CONNECT Machine Connectivity and Model” module. There, the resulting signals are acquired, harmonized and assigned to a standardized semantic machine data model. FORCE EDGE CONNECT then supplies the standardized, harmonized machine data in the form of machine events to a downstream system, for example the SAP DMC (Digital Manufacturing Cloud).

Author: Marc Fröschl (Product Owner)

Your contact person

You want to learn more about the topic? As your contact person, I will be happy to answer any open questions you may have about our solutions. You can reach me at: Oliver.Hoffmann@forcam.com