Highly diverse machine facilities connected simply and digitally – Episode 6: Traceability

In the move towards smart factories, SAP’s Industry 4.0 strategy comprises four key topic areas: Intelligent assets, Intelligent factories, Empowered people and Intelligent products. FORCAM also believes in the importance of these topic areas and supports SAP’s Industry 4.0 strategy with the FORCE EDGE CONNECT connectivity layer connecting our joint customers’ brownfield plant facilities. This makes it possible to provide consistent proof of sustainability along the entire value chain. The FORCE EDGE CONNECT machine connectivity layer and the SAP DMC provide fact-based evidence of your contribution to sustainability in production.

In six articles for common machine types, we outline how companies can use the FORCE EDGE CONNECT connectivity layer to connect all machines – regardless of manufacturer, year, or control system – and process the data in SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII.

Part 6: Batch traceability

Climate protection, consumer protection, product liability, corporate governance: End-to-end traceability of products, components and processes is a must-have in today’s modern factories. It’s all about knowing – at any time – when, where, how, with what and by whom a product was manufactured.

A task of this magnitude can only be solved reliably using data-driven manufacturing. This provides precise analyses of the entire value-add process and can meet the transparency requirements expected of a manufacturing company.

When it comes to traceability, distinctions are made between three types:

- Individual part – The trace object is an identifiable single item

- Assembly – The trace object is an identifiable main component with all assembly steps performed

- Batch – The trace object is an identifiable container.

Batch traceability describes the tracking of production containers. The term “container” is seen as a collective term for all types of containers. These can be anything from small load carriers or boxes in which bulk material is transported to more complex containers such as sorted workpiece carriers (a.k.a. trays).

Accordingly, it is also possible to reflect different ways containers are handled in the production process:

- The standard case assumes that two types of containers are available in a production process, namely an input container and an output container.

- Where sorted workpiece carriers are involved, the input container can also be the output container.

To ensure traceability, the machine or the production process acquires data from sensors such as pressure, flow etc. and assigns this data to the trace object, in our case the container. This will later ensure that it is possible to trace exactly how, and under which conditions, a part was manufactured.

When tracing, the special feature is that not only machine events are transmitted, but also, where necessary, actually acquired trace data, which usually includes a physical unit when the semantics are assigned. Thus, it is clear after the event which physical unit the acquired value corresponds to.

Reference machine, plug-ins, process flow, target architecture

When selecting the reference machine, one must determine which process data is of relevance and needs to be included in the data collected. The same plug-in variants apply to the trace object as to all other machine connection use cases.

When considering the specific process flow, it is important to decide which trace data is to be acquired, which trace data is acquired at what time and what the triggers are for acquiring the trace data.

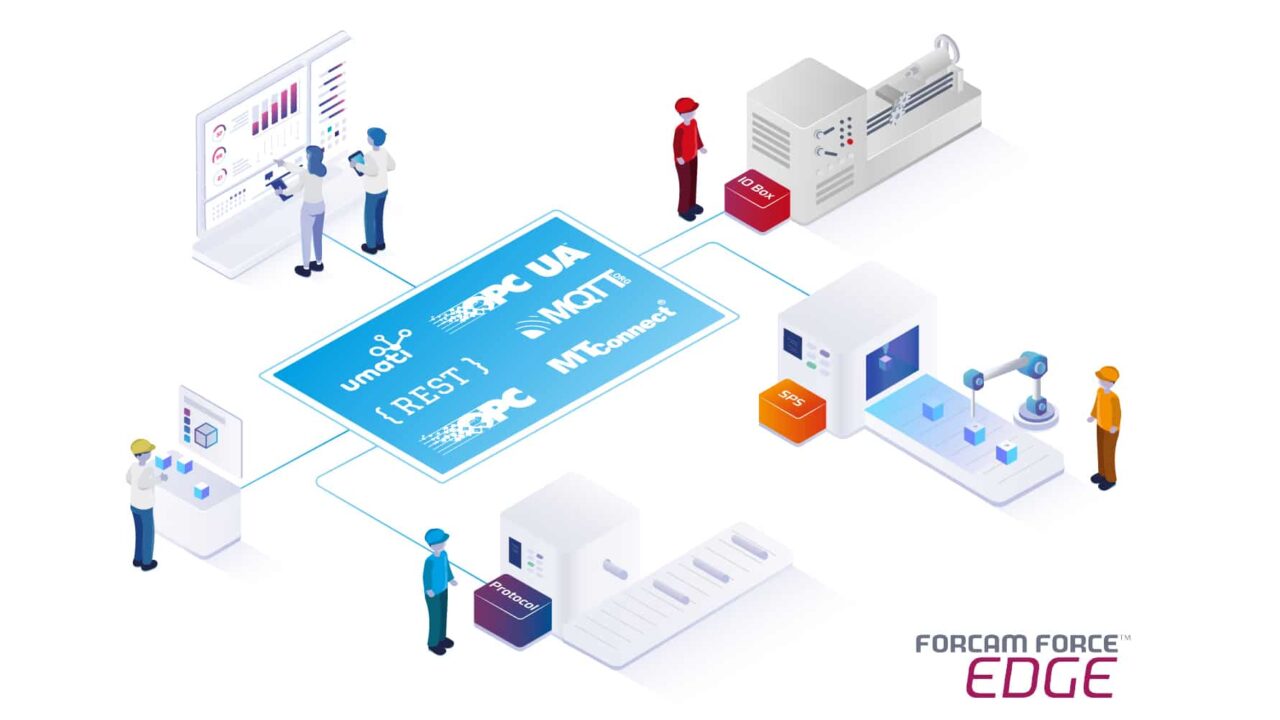

These requirements are mapped onto the FORCE EDGE CONNECT solution portfolio.

The target architecture is structured as follows: The machine supplies trace data (signals) via the FORCAM plug-ins to the “FORCE EDGE CONNECT Machine Connectivity and Model” module. There, the signals are acquired and assigned to corresponding semantics. The “FORCE EDGE CONNECT Machine Connectivity and Model” module delivers this data to a superordinate system, for example SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII.

Author: Marc Fröschl (Product Owner)

About the author

Oliver Hoffmann is the Managing Director at FORCAM ENISCO, responsible for global sales, marketing, partner business, and the digitalization of selected business processes. A business informatics graduate, he has over 25 years of experience selling consulting-intensive software solutions.